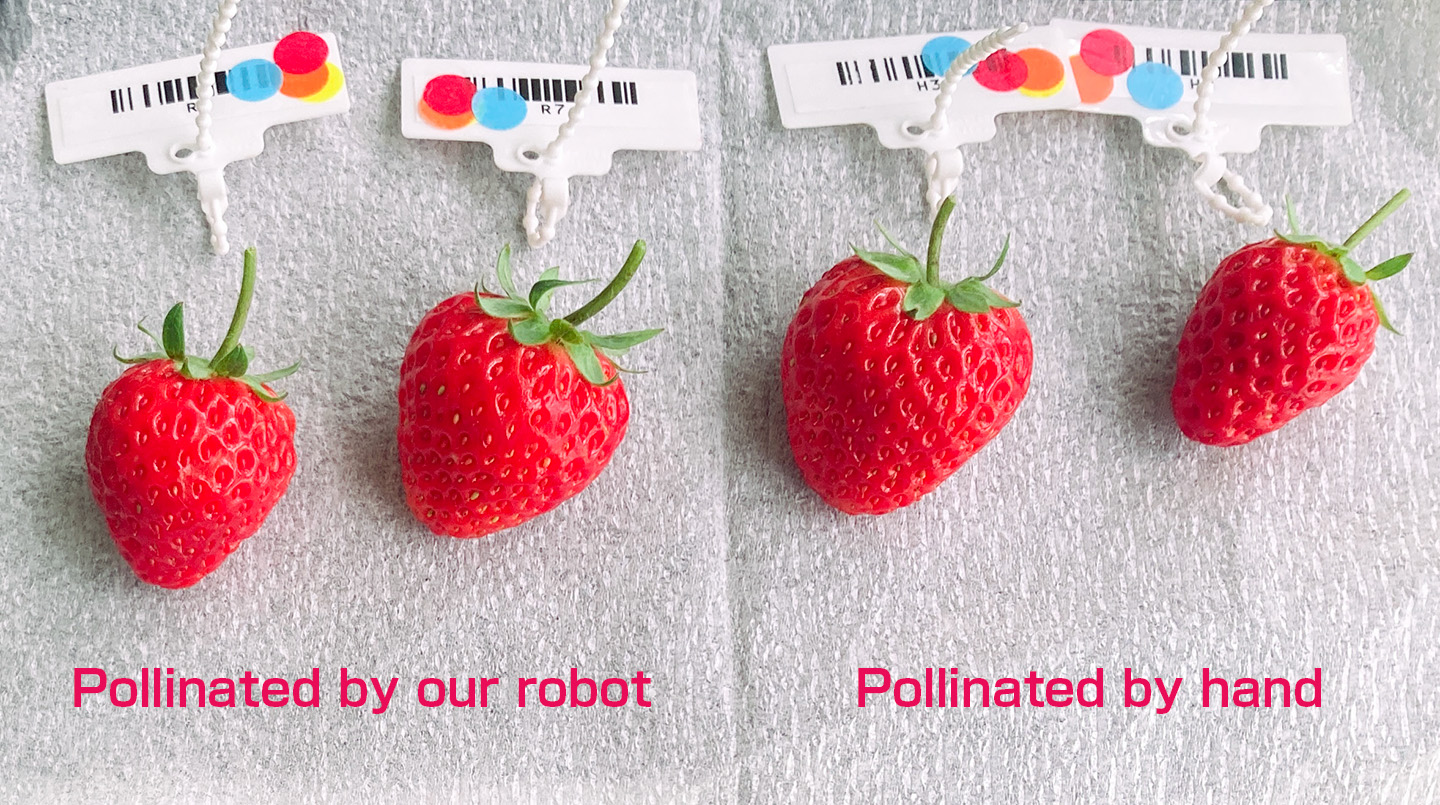

HarvestX was the first company in the world to succeed in the automated pollination of strawberries by robots.

We are developing robotics and AI technologies to solve various problems existing in the agricultural industry.

HarvestX is developing pollination technology to replace bees, emulating the ecology of bees that have coexisted with plants since immemorial.

By using a neural network to estimate the skeleton of bees from videos of them collecting nectar and pollen on flowers, we indirectly extract the features of their pollination behavior. We are conducting experiments to form more beautifully shaped strawberries by applying the extracted features to pollination algorithms. Our robots and algorithms for pollination and management can improve efficiency and quality.

Most of the fruits that we see today can only bear fruit with the process of pollination. Pollination refers to the attachment of pollen released from the stamen to the pistil, and the red and robust strawberries result from this plant's reproductive activity. In the case of strawberries, both stamen and pistil exist in the same flower, and the fruit will bear fruit depending on whether the pollen from the stamen reaches the pistil. In nature and farms, insects such as bees collecting honey move around on flowers, and pollination is carried out by the pollen sticking to their bodies. Suppose pollination is not evenly carried out so that pollen evenly attaches to the pistil. Then, only certain parts of the pistil will receive pollination, causing the fruit's shape to become distorted.

Indoor farms are a harsh environment for the insects responsible for pollination. Strawberries produce little nutritious nectar, and no other plants are on the indoor farm, so bees cannot sustainably live in such an environment. As a result, bees are typically eradicated every few weeks or months in indoor farms, and new hives are introduced. However, bee populations are declining globally, and using and disposing of living organisms is not sustainable or ethical.

Using bees can pose a risk of disease outbreaks in indoor farms. Dead bees can become sources of mold, and new hives can bring in diseases. Pollination by bees cannot control how many pollinations are performed on one plant or evenly attach pollen to the pistil, leading to variation in the appearance, taste, and yield of the fruit in current agriculture. Efficiency and quality improvements can be achieved through pollination and management using robots and algorithms.

HarvestX is developing a highly accurate yield prediction system using flower and fruit maturity information. The system statistically processes data on the flowering status of each seedling and the growth rate of the fruit to create a more productive growing environment for seedlings.

HarvestX developed a fruit maturity classification algorithm before the yield prediction system. This algorithm classifies strawberries into four detailed stages, from the initial fruiting state to ready for harvest. Using the algorithm to determine the fruit’s maturity makes it possible to estimate the harvest time, preventing human judgment variations correctly.

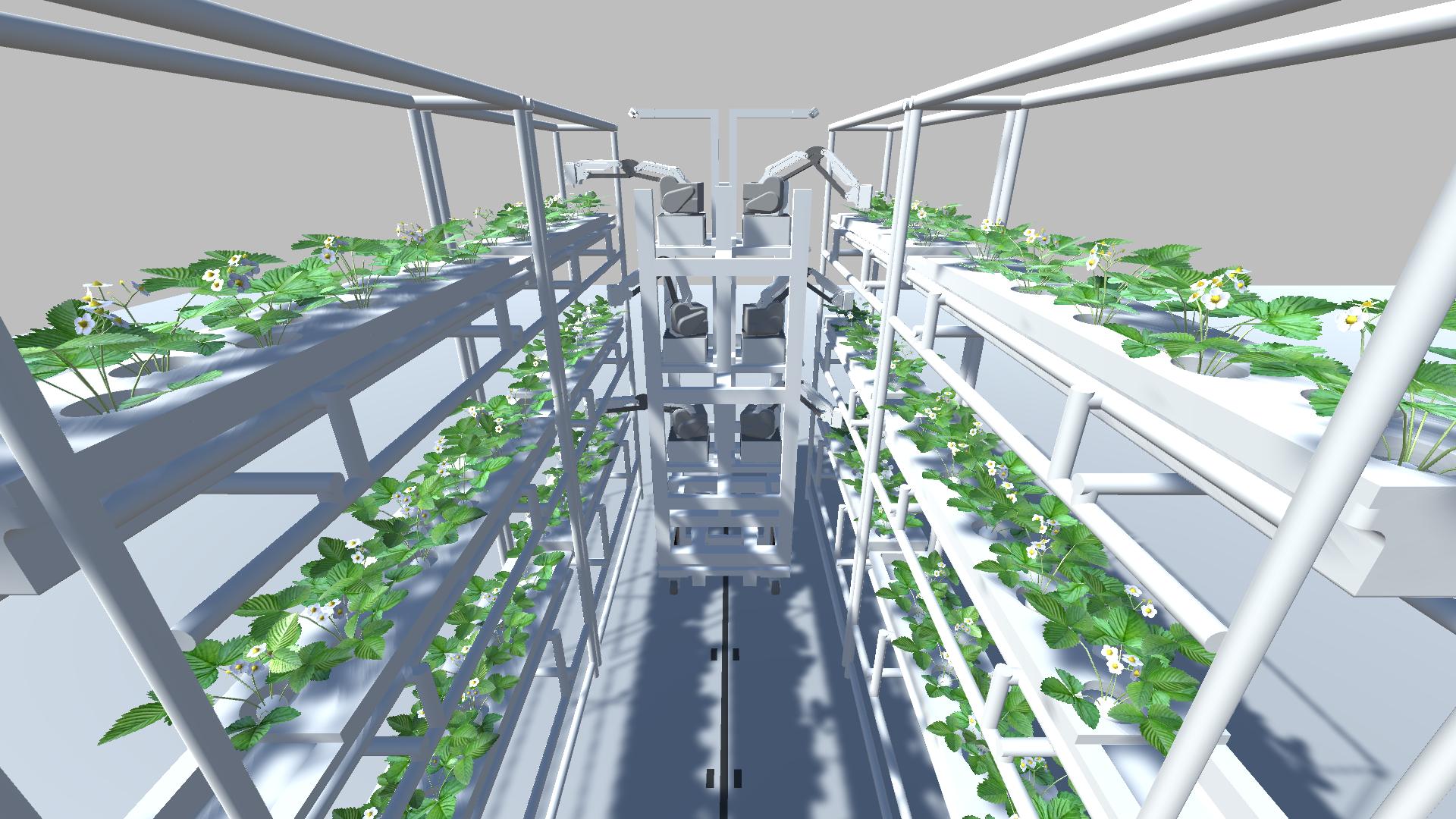

ROS/ROS2 is a set of software libraries and tools that support the rapid development of robot applications that have seen a rapid increase in downloads in recent years. Introducing a unified rule for inter-software communication interfaces can significantly increase the efficiency of robot development. HarvestX has currently developed about 100 ROS2 packages and is advancing its development. Using the power of ROS2 interfaces, we are creating robots that can flexibly respond to various challenges in various plant factories. In addition, we have developed a simulator that replicates our site to efficiently and safely solve the challenges in the plant factory as a team, and we are using it for development.

HarvestX releases some of the packages created to build robotic systems.

It aims to contribute to the development of the field of robotics and the community with software for automation created in the process of establishing a new food production infrastructure.

To distribute pollen evenly on the pistil, the direction of contact of the pollination brush must match the order in which the flower is facing.

Conventional detection methods can only identify the position of the flowers. They cannot recognize the direction of flowers and from where the pollination brush should approach.

HarvestX has developed a machine learning technique that uses 3D models and rendered images to generate supervised data on flower orientation. By applying a neural network that detects the direction of a person’s face, we have established a technique for estimating the directions of flowers.

This technology will bring stable production of beautiful strawberries to indoor vertical farms, which honeybees can’t achieve.