SCROLL

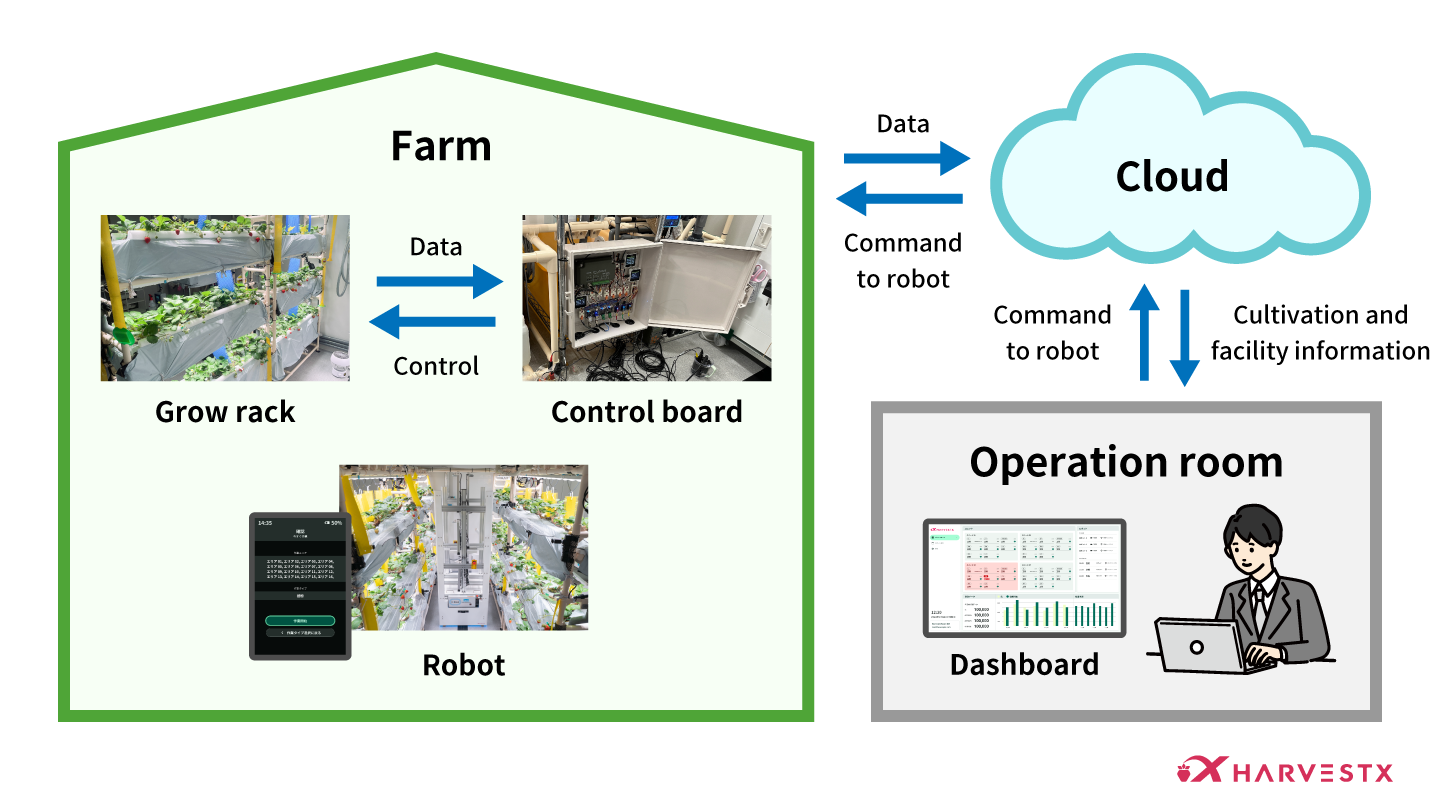

HarvestX provides a package for artificial light indoor farms that enables strawberry production in any location and environment through highly accurate pollination using advanced robotic technology and environmental control using sensing technology.

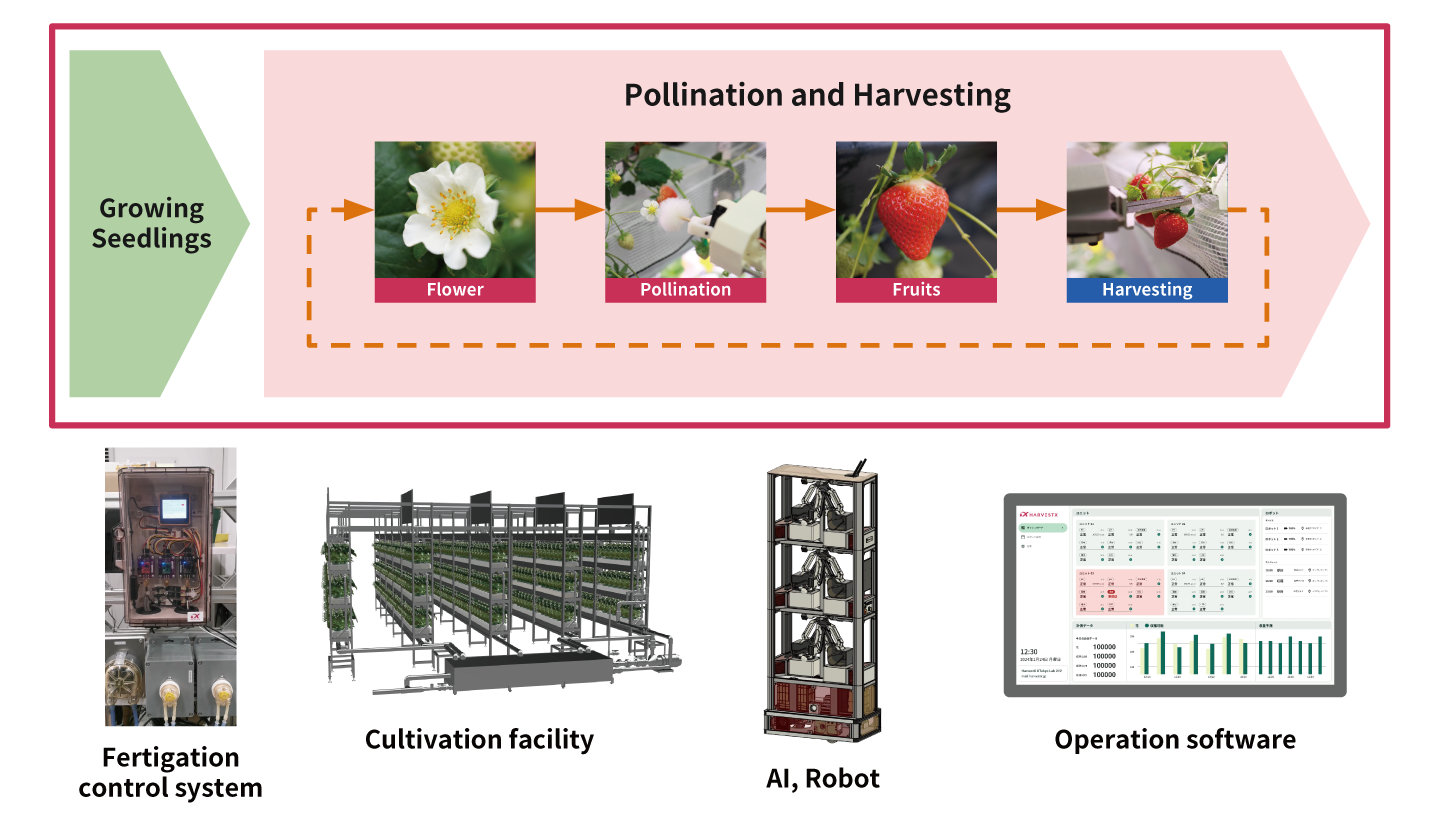

We support the entire process from seedling cultivation to strawberry harvesting in indoor farms by providing cultivation equipment, robots, AI, operation systems, etc.

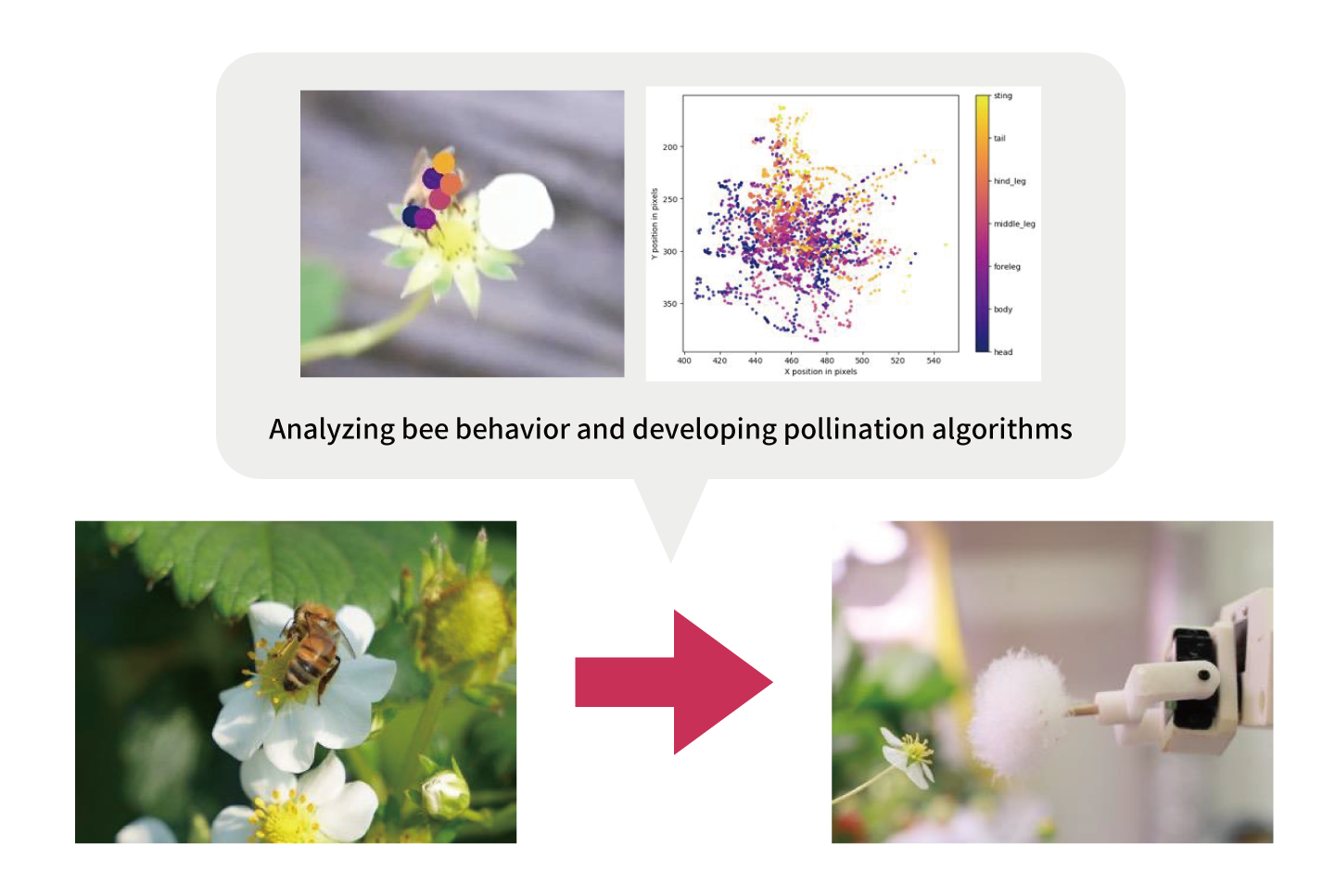

We analyzed the behavior of bees, which play an important role in flower pollination, and implemented it into our algorithm.

The combination of core technologies for the use of AI and robotics (Patent No. 7090953) and confidential technologies such as materials selection, rotational frequency adjustment, and three-dimensional recognition ensure our advantage.

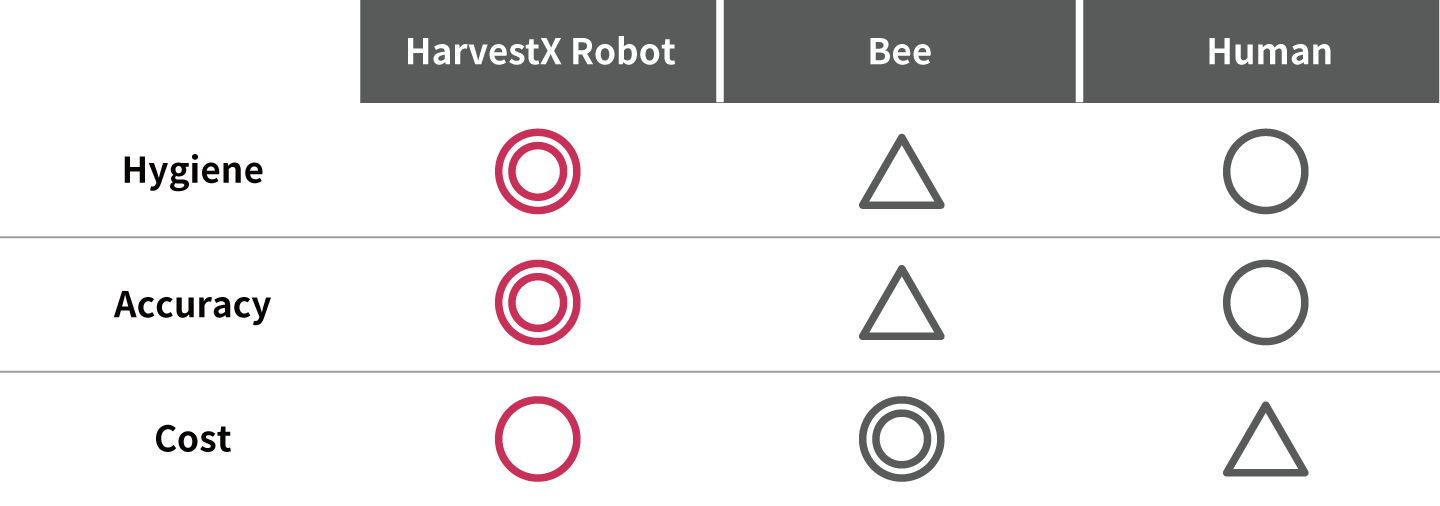

Low-cost, high-precision pollination and a hygienic environment without using bees make the strawberry plant factory ideal for food production.

Currently, we are the only company that can provide both cultivation and automatic pollination in one integrated system.

We are developing technologies through experiments to provide better service.